Posted By: Andrew Sager on December 18, 2024

A historical overview of the barcode, tracking its development from its initial concept to the pivotal role it plays in inventory management and the global supply chain.

Most of us have a good understanding of what a barcode is and what it's used for. They are on just about every inanimate object; anything that needs to be accounted for or run through a checkout line will have one. They have become so ingrained in both our personal and professional daily routines that it's difficult to imagine a time before barcodes existed. In this blog, I'll cover the history of the barcode, explain how this single invention helped shape global commerce, and discuss ways businesses can use barcodes to improve inventory management accuracy and transparency.

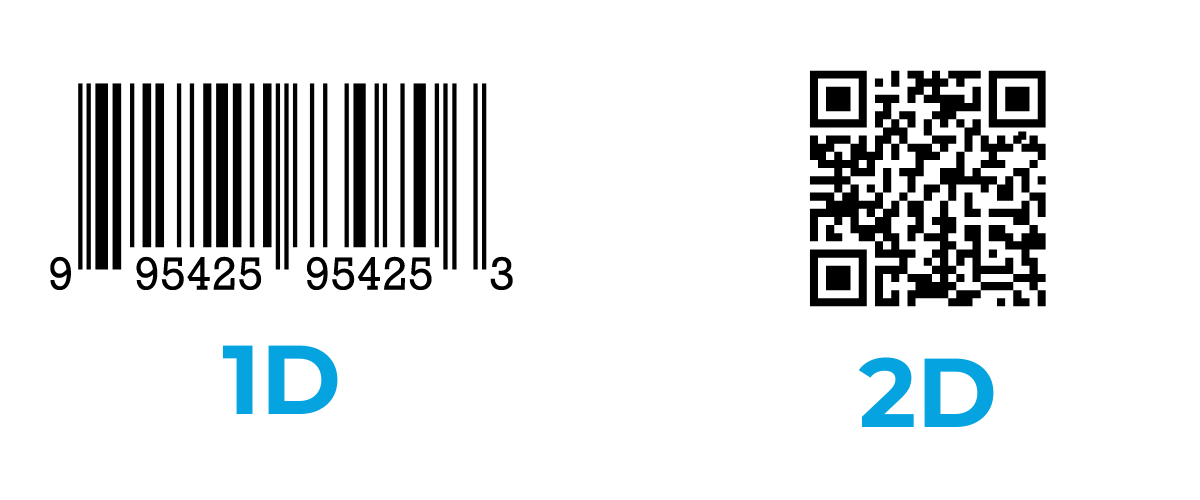

A barcode is a machine-readable representation of data, typically in the form of parallel lines (1D barcode) or geometrical patterns (2D barcode), and is commonly found on most products, packaging, and printed labels. They contain item-specific information about the manufacturer, product type, size, price, and other pertinent data useful for businesses handling products throughout the supply chain.

The barcode was invented in the early 1950s by two engineers from the Drexel Institute of Technology, Norman Joseph Woodland and Bernard Silver. The concept of the barcode originated when the head of a local grocery store chain approached the Dean at Drexel with a proposition. He hoped to leverage Drexel's engineering school to come up with a method for quickly capturing product data during the checkout line. When the dean turned down the idea, Woodland and Silver decided to tackle the challenge themselves. They devised a strategy to encode data on products by creating a graphical representation of Morse code using lines drawn in the sand, eventually leading to the first barcode-like concept [1]. But there was one problem. The technology required to read the barcode and extract its data in an automated fashion didn't exist.

Fast forward 20 years, and the first barcode scanner was put to use in a checkout line at a Marsh supermarket in Troy, Ohio. The scanner was used to facilitate the purchase of an item marked with a UPC barcode (Universal Product Code). Can you guess what product it was? A 10-pack of Wrigley's Juicy Fruit chewing gum! [2] Some doubted UPC barcodes on smaller packages could be scanned, but Wrigley's proved the skeptics wrong.

It wasn't until the 1980s that the barcode realized its true potential when companies like Walmart and Kmart, which deal with thousands of products, began utilizing barcode technology for inventory management and product cataloging. By automating data capture and retrieval, barcodes not only revolutionized the way grocery stores and retailers track items but also transformed the global supply chain. Today, barcodes provide increased efficiency, accuracy, and productivity across many industries. Take healthcare for example. Many pharmacies and hospitals have adopted barcodes for tracking medications and identifying admitted patients. This advancement has significantly improved patient safety measures by reducing errors and ensuring that healthcare providers comply with regulatory standards.

There are numerous types of barcodes, each designed for specific purposes and industries. However, they can be categorized into two main types: 1D and 2D barcodes.

The future of barcode technology is in a constant state of evolution and many businesses are starting to realize that 1D barcodes simply can't keep up with growing consumer demands. Consumers are seeking easier access to product information, traceability, and authentication for the items they buy. As a result, the industry is pushing for a transition from 1D to 2D barcodes by 2027. This effort is being led by GS1, an international barcode standards organization. They're calling it Sunrise 2027 and it will require all retailers to have the ability to scan 2D barcodes at the point of sale [3].

The transition from 1D to 2D barcodes will have a significant impact on the entire supply chain and consumers alike. So, if you're considering using an inventory management system for your business, you'll want to make sure it supports 2D barcodes. Scan IM's inventory management system is designed to support both printing and scanning of 1D and 2D barcodes. Making it a great option for any business looking to improve inventory control while future-proofing their operations.

If you'd like to give Scan IM a try, we offer a risk-free 14 day trial that allows test out the software and make sure it's the right fit for your inventory needs. Experience the transformative power of inventory management in the palm of your hands and give Scan IM a try today!

Sources

[3] https://www.gs1us.org/industries-and-insights/by-topic/sunrise-2027

Upgrade Expires In: